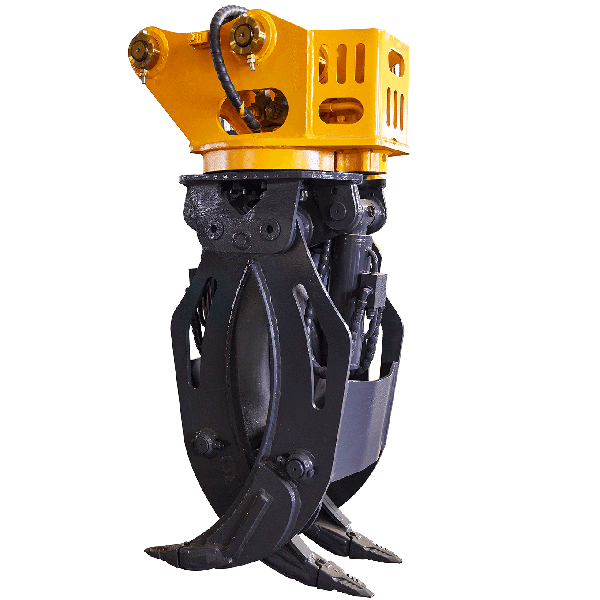

Factory Making Double Teeth Ripper - The Excavator Hydraulic Rock Ripper – Donghong

Factory Making Double Teeth Ripper - The Excavator Hydraulic Rock Ripper – Donghong Detail:

description

1.Range from 4-75 tonnage excavator

2.Apply all the power of your excavator at one point for maximum ripping efficiency

3.Replaceable and wear shroud.

4.Added side wear protection to extend life of ripper (for excavators bigger than 10 tons)

5.Extra thick steel shank for increased strength

6.Ripper reduces excessive stresses on your excavator.

advantages

For excavator tooth ripper we produce single tooth ripper and double teeth ripper, It could be used for digging hard soil, frozen soil, soft rock, weathered rock and cracked rock. It also can remove the root of the trees and other barriers. Donghong use high-strength wearable steel plate, such as Q345, Q460, WH60, NM400, Hardox 400 as the material. And OEM order is available to us.

When your job demands breaking through though surfaces (such as rock, tarmac, or paving), you need a strong, reliable and durable excavator ripper.

With careful selection, a quality excavator shank will help you get your work done quicker, so you can be more productive.

classification

Here are a few things to look out for when selecting an excavator ripper:

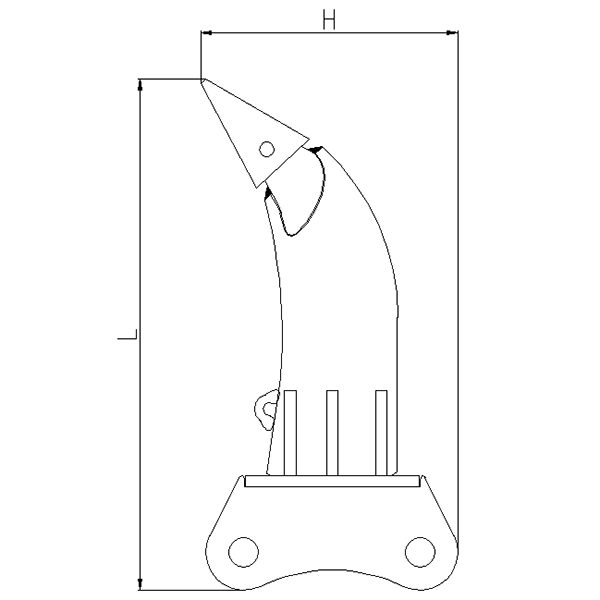

1. Advanced shank geometry

The shank should be designed to break through and rake the toughest surfaces with ease allowing for efficient ripping under a variety of conditions. Choose a ripper with a streamline design. This will ensure your shank rips the material rather than ploughing it. Ripper shape should promote efficient ripping. This means you’ll make easier, deeper rips without putting too much of a load on the machine.

2. Proper construction

Heavy duty robust construction will ensure your excavator ripper has the increased strength and durability to last for years to come. Cheeks should be reinforced for added durability.

3. Manufactured from high strength steel

Be sure to select an excavator ripper that is manufactured from high strength steel for a longer lifespan.

4. OH&S compliant

Naturally, all excavator rippers used on your earthmoving equipment should be manufactured to comply with OH&S requirements.

5. Wear a protective device on ripper’s shin

Ripper blade protection provides further protection and life in rock and abrasive applications.

6. Ripper length

A good supplier should carry a range of excavator rippers of various lengths. Be sure to get advice where necessary on what is best for your application.

specification

| Model | Unit | DHG-mini | DHG-02/04 | DHG-06 | DHG-08 | DHG-10 | DHG-17 |

| Suitable Weight | ton | 1.5-4 | 4-8 | 14-18 | 20-25 | 26-30 | 36-45 |

| Pin to pin distance | mm | 85-200 | 220-310 | 390 | 465 | 515 | 580 |

| Total width | mm | 310 | 425 | 540 | 665 | 735 | 800 |

| Total hight | mm | 600 | 670 | 910 | 1275 | 1560 | 1550 |

| Diameter | mm | 25-40 | 45-55 | 60-70 | 70-80 | 90 | 100-120 |

| Arm width | mm | 90-150 | 180-230 | 220-315 | 300-350 | 350-410 | 370-480 |

| Weight | kg | 50 | 80 | 280 | 400 | 550 | 900 |

Product detail pictures:

Related Product Guide:

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Factory Making Double Teeth Ripper - The Excavator Hydraulic Rock Ripper – Donghong , The product will supply to all over the world, such as: Argentina, Cologne, Detroit, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!